COFE® was the first and remains the most advanced Warehouse Execution System! COFE® organizes and optimizes order fulfillment by sequencing and synchronizing work flows. This solution ensures the most efficient use of all work resources — space, equipment and personnel.

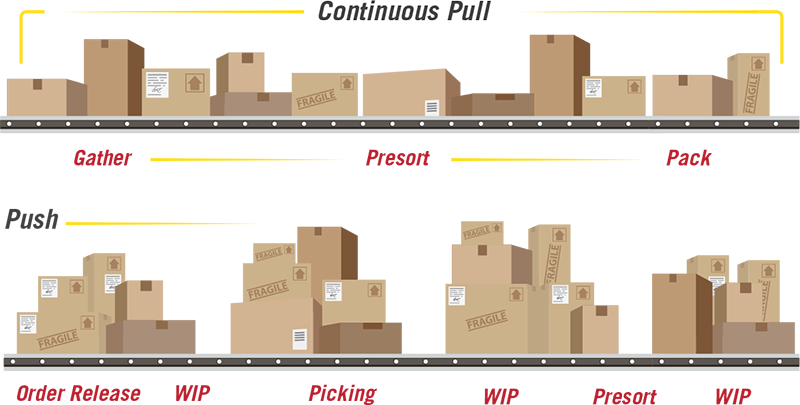

If you’re working off a plan including waving orders and buffering work, you will always have unavoidable warehouse inefficiencies that can only be solved by creating a waveless process.

What is WES?

A warehouse execution system, or WES, is a software solution that can direct all of the processes that take place inside a distribution center. The WES works in real-time to organize, sequence and synchronize all warehouse resources: material handling equipment, devices, and employees. This reactive solution moves orders in a continuous flow. If a condition changes in one part of the process, the system will reprioritize work to expedite fulfillment.

WES vs. WMS vs. WCS

In recent years, the material handling industry has categorized the various software platforms for operating distribution operations using the terms Warehouse Management System (WMS), Warehouse Execution System (WES), Warehouse Control System (WCS) and machine control systems. These terms have arisen to distinguish key features and operating paradigms between the contributions of various software systems.

In addition to these systems, there are labor management systems, order management systems, material and resource planning systems, transportation management systems and other systems that distribution centers may deploy to manage the entire operation.

In an ideal distribution world, one would prefer a single software system that could provide all of the requirements for driving an operation. However, no such platform currently exists.

The WES sits between the WMS and the work resources necessary to accomplish the work plan, and it directs both people and machinery in real time as to execute the plan. The biggest distinction between the WMS, the WES and the WCS is the decision-making processes themselves and their timeliness.

The WMS creates work plans and the time to compute a work plan is not critical to the operation. Work can be planned hours before the work is to be executed. The WCS, however, is very critical to time or the timing of direction to control the material handling equipment, which requires real-time direction to operate.

While the WCS is capable of making real-time decisions within its silo of machinery, the operational direction is provided by another system. That leaves the WCS with little operational decision capability and relegates it to execution of a plan.

Traditional WMS computing architecture is not based on making real-time decisions. To effectively make real-time decisions, the system of choice (WMS, WES, WCS) needs to know the status of all of the required resources at the decision time.

Some WMS providers continue to improve the timeliness of decision making, at times referring to “near real-time” operations. However, until they achieve real-time operation across all work resources, the distinction between a WES and WMS will remain.

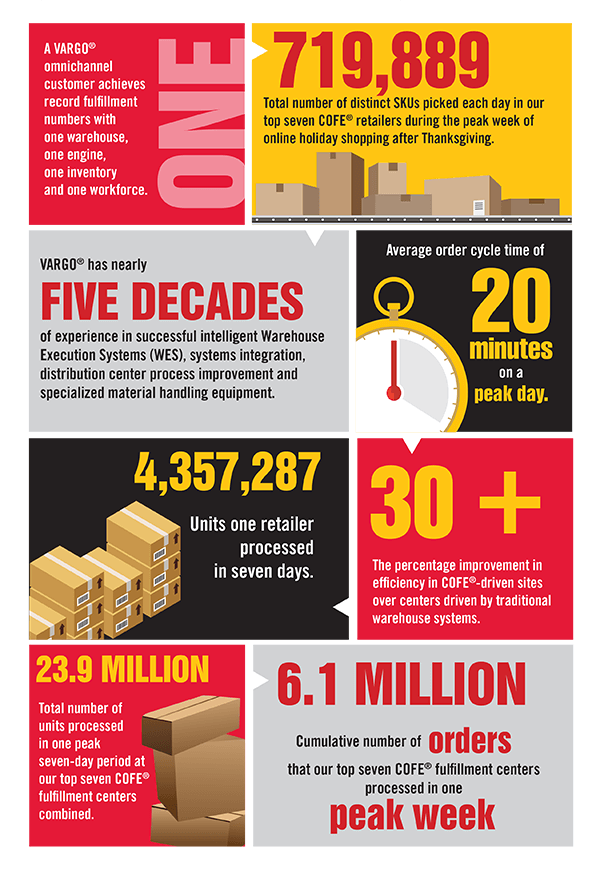

The Proof is in Our Numbers

VARGO®’s team of warehousing, fulfillment and distribution center experts have been exceeding customer expectations for more than five decades. Seventy percent of VARGO®’s business comes from custom-engineered material handling systems, each tailored to the customers’ needs. But don’t take it from us — the proof is in our numbers!

Adaptive, Scalable, Fast

Warehouse fulfillment shouldn’t be complicated. COFE® is a powerful and customizable software solution that controls all the processes that take place inside a distribution center. Unlike traditional warehouse control software solutions, it controls material handling equipment as well as the devices, people and processes inside a distribution center. COFE®, integrates and synchronizes your DC workers with the operation of the equipment. It is the Warehouse Execution System software that does for fulfillment what Lean did for manufacturing.

We offer a variety of modules that allow COFE® to be customized for your specific application.

Dynamic Labor Balancing

- Provides real-time, system-directed labor balancing across multiple work zones

- Bases decisions on current priorities and workload demands

- Synchronizes the operation of all work zones

- Accounts for “zone transfer” penalties in excessive worker movements

Sorting Machine Optimization

- Real-time optimized decision item sortation

- Increased sortation capacity by 28%

- Reduced “problem orders” by 75%

- Reduced processing and material handling labor

- Allows workers to work to their own capacity

Next-order Optimization

- Makes real-time decision of the next order to release

- Bases decisions on order priority, ship requirements, order ages, picker locations and available inventory

- Allows nearly immediate processing of priority orders

- Determines what orders are “not picked” in resource-limited operating conditions

Revolving Batch Picking

- Eliminates low productivity wave transition periods

- Maximizes continuous resource utilization

- Levels processes, eliminating harmonic peaks and valleys behavior

Reporting & Management Tools

There are more than 150 standard COFE® VIEW reports and management tools to assist you in keeping pace with the real-time activities happening within your distribution center. In addition, COFE® VIEW’s intuitive design allows even the most novice of users the ability to create custom reports in just minutes to meet their individual needs.

COFE® VIEW now offers two additional modules: COFE® VIEW Mobility and COFE® VIEW Analytics.

The COFE® VIEW Mobility module has several key features, including:

- Forecasting and variance analysis: Managers can set production goals for the day and track performance against those goals by shift.

- Labor planning tools: COFE® VIEW Mobility will assist with anticipated labor requirements based on production goals, and it will recommend functional allocation of actual staff using historical production rates maintained in COFE® for a client’s specific operation.

- Intuitive alerts based on performance: The system will provide early warning on performance and production issues, in an easy-to-understand format, allowing managers time to react.

- Access to equipment and processing controls: Managers will be able to turn on (or off) equipment, and enable or disable workstations, etc., right from a device, without having to return to a desktop or a control room to do that.

- Browser-based access: Managers can access system information from anywhere, anytime, allowing traveling executives or shift supervisors access to view in real time what is happening in their distribution centers while they are away.

- Responsive and intuitive: Works on any device and in any orientation — landscape or portrait — and various screen sizes, providing users the freedom to access information the way they want it.

- Smart device RF integration: In some instances, an employees’ devices will replace the need for expensive RF devices by providing the same RF functionality except it will be accessible through a smart device.

The COFE® VIEW Analytics module provides managers with all of the features of the Mobility package as well as the ability to measure, visualize and manage operations in real time to a much more granular level. It also offers flexibility to build individual custom statistical and analytical reports. This module has several statistical tools and interactive visualization features that allow decision makers to:

- View visual presentation of operational data in a much more in-depth way.

- Drill deeper into data for more granular details.

- Track and evaluate key performance indicators, discover trends and draw comparisons.

- Develop online dashboards and visualizations to optimize processes. Aggregate information from other industry-standard database sources in conjunction with distribution center operational data. This reduces the dependency to sift through multiple external reports and the need to export data from various systems into some other application to build to cross-system reports and analytics.

Watch Our Videos

The emerging role of the Warehouse Execution System (WES) – A Supply Chain Brain interview with Art Eldred from VARGO®

The emerging role of the Warehouse Execution System (WES) – A Supply Chain Brain interview with Art Eldred from VARGO®

The difference between waveless fulfillment and traditional waves.

To see the power of COFE®, schedule a FREE consultation.