From Capacity Limits to 200% Throughput Gains — See How VARGO ® Helped Torrid Orchestrate Fulfillment Excellence

The ecommerce boom has led to a new wave of consumers that expect orders to be processed and shipped faster than ever before. For retailers, that means ensuring their facilities have the capacity to accommodate a high volume of orders efficiently and accurately. When Torrid, one of the largest direct-to-consumer apparel brands in North America for women sizes 10 to 30, realized its systems had reached capacity, were underperforming and unable to achieve the desired throughput needs, the team at Torrid reached out to the experts at VARGO® for a solution that would help increase the capacity of its current automation technology resources and make better use of its labor.

Solution

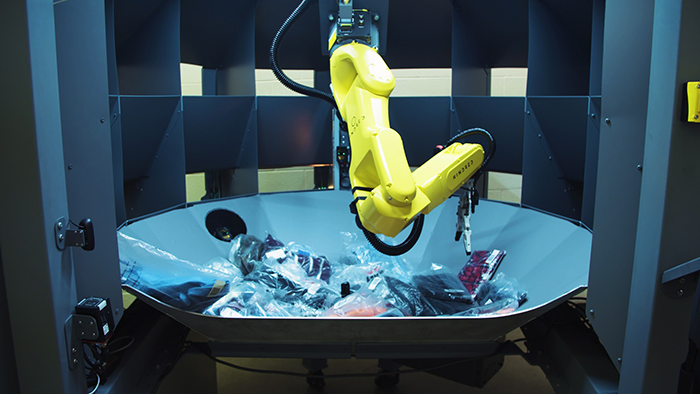

VARGO® aimed to maximize the value of Torrid’s existing automation investments by increasing peak daily throughput, providing significant picking efficiency gains and reducing order cycle times. VARGO® worked closely with Torrid’s senior leadership on implementing its adaptable, highly configurable WES, COFE®, to re-control the existing mechanical elements within its distribution facility while more importantly, establishing a sustainable, waveless flow of picked products through order completion. These changes included removing the existing mechanical buffer system, creating a reserve replenishment methodology to the active pick model to replace the existing model and retrofitting the unit sorter system to a sort-to-putwall design. VARGO® also partnered with Matthews Automation and BEUMER Group on the rework of the existing controls and sortation equipment on portions of the system to fit the new waveless design.

Results

By prioritizing the process needs and desired outcomes before pursuing new automation or mechanical upgrades, VARGO® was able to significantly enhance building throughput and operational efficiency with limited additional CapEx spend. The solution implemented by VARGO® exceeded projected returns and continues to outperform industry benchmarks in picking efficiency and order cycle times. Torrid has since doubled its outbound volume, and the team reports that the system is significantly easier to operate compared to previous solutions. Key performance changes include 200% increase in capacity/throughput, 75% faster order completion times and 66% reduction in exception orders.

“In brownfield opportunities like Torrid, COFE®, our Warehouse Execution System (WES) acts as a unifying intelligence layer that synchronizes labor, automation, and inventory in real time—unlocking hidden capacity, improving flow, and dramatically increasing throughput without costly infrastructure changes or significant disruptions to the business in many instances.”

Bart Cera, CEO of VARGO®