Basic Host Interface and Integration

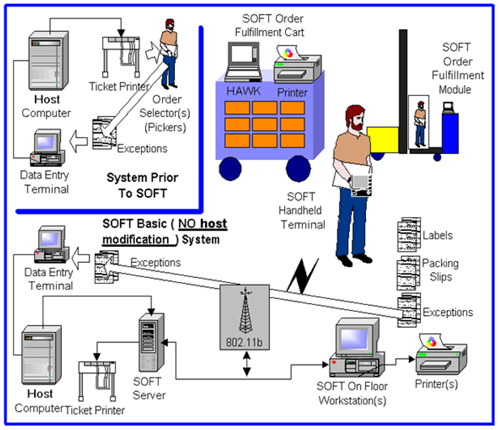

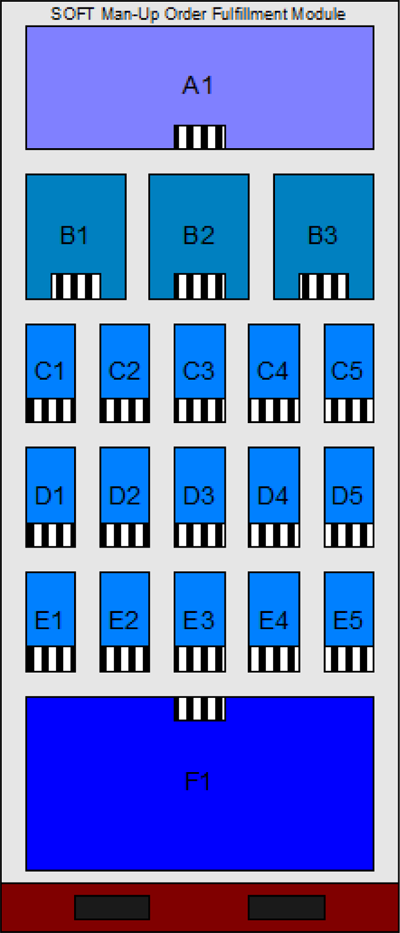

This paper describes an application example of the most basic interface of SOFT™ system using Hawk™ Model 201 smart carts into a paper based pick ticket system. Using this interface, absolutely no modification to the existing information system (host) is necessary. This interface will integrate with literally any information system, any hardware platform and any WMS. Additionally the interface will support all SOFT devices, man-up fulfillment modules, SOFT handheld terminals and wearable devices, and SOFT terminals for mounting on various warehouse equipment.

Definitions

Host—the computer currently connected to the pick system printers.

SOFT System—the computing system, user interface devices and all associated smart picking carts, modules. The SOFT computing system organizes and oversees the picking process

Existing printers—the printers that are used by the host to print pick tickets, packing slips and shipping labels.

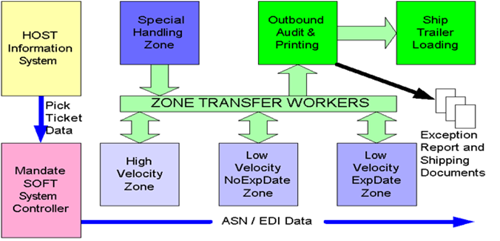

Interface Overview

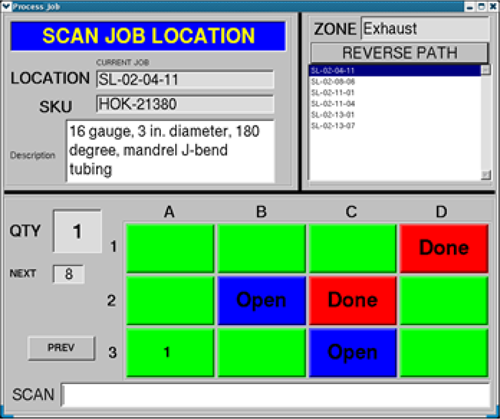

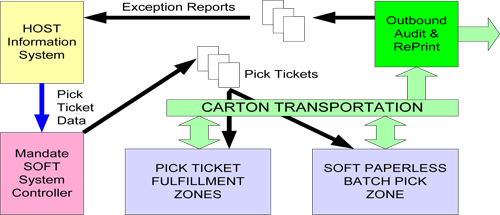

In this most basic interface, SOFT intercepts the pick tickets as they are sent from the host computer to the pick ticket printers. Internally, SOFT identifies the line items that are to be processed through the smart batch picking system and the line items that are to be processed with pick tickets. SOFT prints pick tickets for the orders to be picked from tickets. The paperless picking orders to be processed with SOFT picking devices are dynamically scheduled for picking in the most efficient sequence.

In this most basic interface, picking exceptions for the paper based pick tickets are handled as in the paper system. Picking exceptions from the smart paperless picking devices are recorded and viewed in report form. The report is printed so exceptions can be processed just as the paper based pick ticket exceptions are processed.

Interface—Host to SOFT™ System

The host normally connects to the SOFT System via a single printer port connection. To the host, the SOFT System looks exactly as the printer. The SOFT System receives picking orders by “extracting” and “decoding” information that is sent to the printer. The host software or hardware is not modified, it just continues to print pick tickets as normal. A switch box may be provided to make this connection.

Some systems may use multiple pick ticket printers. Normally in these situations only one ticket printer connection is needed for connection to SOFT. To the host computer, other ticket printers should appear “offline” and all print tickets are directed to the SOFT System. If multiple pick ticket printers are still necessary to support print volume, they are all connected to the SOFT computing system. Switch boxes are provided as needed. Internally, the SOFT System will examine the print ticket data as it is received from the host. It examines the information on a line-item by line-item basis. Within the SOFT system, there are multiple configurable means of organizing and processing work based on operational requirements. The actual means of filling the orders is independent of the interface and integration with the host.

Processing of work within SOFT may be any of the following:

- Orders completely filled by SOFT devices

- Orders completely filled by paper pick tickets

- Orders completed by both SOFT devices and by paper pick tickets

SOFT will create all the necessary pick tickets, labels, packing slips and completion-exception reports depending upon the order fulfillment means. SOFT also provides means of consolidating orders for shipment.

Interface—SOFT System to Host

Information required from the SOFT System (order line-item completion information) is normally provided as an exception report for the basic interface model. This information may be provided in many ways, however, if the system design requirement does not include host modifications, SOFT will provide an “Exception Report”. This report will be delivered to the host system for entry just as any exceptions on the existing system would have been delivered. The exception report format is provided as required for operation.