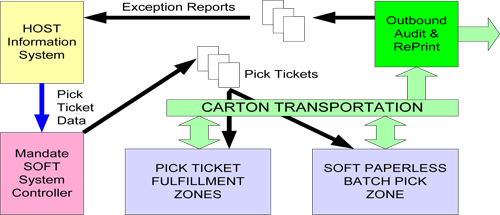

Integration of Paperless Batch Picking

This paper describes an application example where a Mandate® based SOFT™ System is integrated into an existing facility that uses a paper based pick ticket system. The existing operation fulfills orders from multiple stock areas or zones. The existing operation creates “order-carton” pick tickets. An order-carton is the sub-division of a customer order cartonized to meet handling, weight or volume constraints. Items are picked directly into the shipping carton. Pick tickets may include items from multiple pick zones. The pick ticket includes two shipping labels, one for the top of the shipping carton, and one for the side of the shipping carton. The completed pick ticket also serves as the carton packing slip. A carbonless copy of the completed packing slip portion of the pick ticket serves for exception reporting to the existing information system.

The current operation is modified to use five SOFT Hawk™ Model 201 smart carts to fill orders from one of the fulfillment zones. Approximately 88% of the orders have one or more items filled in the Hawk™ fulfillment zone although only 23% of the units are filled from this area. A near insignificant percent (less than 4%) of orders are filled completely within the fulfillment zone serviced by Hawk™. The existing host system is not modified.

Host Interface

The host interface is a basic SOFT interface where the SOFT System captures all printed pick-ticket data extracting and organizing work from the pick ticket and printing pick tickets as necessary. Pick exceptions are reported to the host using paper based data entry defined by system configuration rules.

New Operation Overview

All pick tickets are printed by SOFT on two existing reconnected printers. The print tickets are categorized into three groups. One group, tickets with absolutely no SOFT zone items, is called “NSZ”. Another group has all items from the SOFT zone and is called “SZO”. The last group is tickets with items mixed from both zones and is called “MZI”. SOFT provides configurable means for handling pick ticket printing for each of the groups depending upon operational needs. In this application the number of SZO tickets are negligible and order fulfillment is near 100%. Due to this, SOFT is configured to print all items on a normal pick ticket. The sequence of the line items on the ticket is modified to move all the SOFT items to the end of the list and a dividing message (in this case a line) separates the SOFT items.

Tickets are printed in “starting zone” groups and delivered to the initial pick zone. This applies to the SZO tickets which are delivered to the SOFT fulfillment area.

Hawk order fillers (workers) identify a new active order carton by scanning the carton label. New active order cartons can be added at any time. When a new active order carton is scanned, the Hawk “cell” (cart location of the carton) is also scanned to record where the carton is located.

SOFT provides continuous dynamic adaptive batching. All of the active orders on the Hawk are examined line item by line item to determine the nearest next item to fill. The worker will normally fill this item; however, the worker may also select any other item to fill. SOFT automatically adapts to this situation and reorganizes the work to determine what is best to do next based on the location of the worker. This dynamic optimization is the foundation of Mandate®, the platform upon which SOFT is constructed.

This example application is configured to allow new order-cartons to be activated immediately upon the completion of an existing active carton rather than having to wait to reach a load/unload location. In this application, the completed carton is stacked on the top shelf of the Hawk and a new carton-order is started in the Hawk cell. SOFT Zone Only (SZO) tickets are placed on the Hawk and new orders are activated on the fly.

When a carton is moved from the Hawk the worker scans a “zone transfer location” where the carton is placed. Mandate® tracks and logs the last known location of all cartons.

Zone transfer workers move cartons manually between zones. The workers pick up a pallet from a designated zone transfer spot and deliver it to the designated zone.

Handling Pick Exceptions

In this application, the handling of exceptions is configured to have fulfillment shortages recorded by the worker on the pick ticket/packing list. A carbonless copy of the pick list with the recorded shortages is delivered to a terminal on the existing host system for data entry. The host system handles all exceptions identically and transparently.

Outbound Audit, Creation of Shipping Documents & Shipping

This application example has two SOFT outbound audit workstations. All of the carbonless copies of the pick list with the recorded shortages are removed at these stations. These stations are also used to do sample QA checks on outbound cartons as well as shipping documentation reprinting.