Mobile Order Fulfillment Work Stations

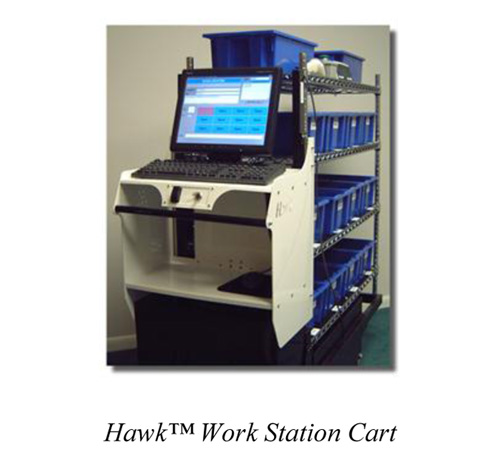

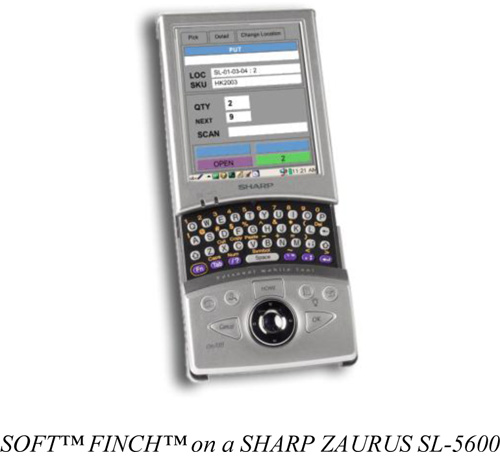

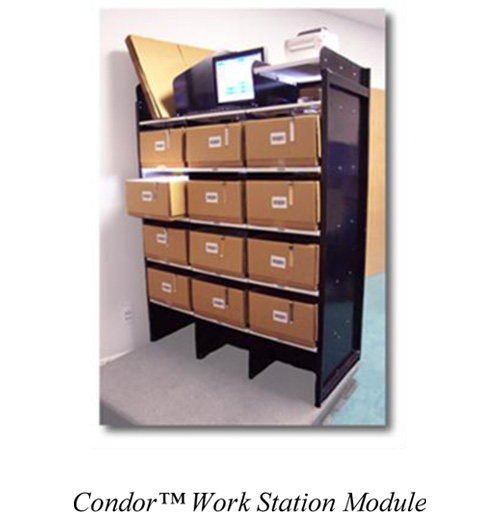

Mobile fulfillment workstations supported with Smart Order Fulfillment Technology (SOFT™) offer the following features to be considered as specific business needs dictate:

Basic Functionality

- Mechanical configuration to efficiently operate in the required stock storage area (size, maneuverability, reach, accessible height)

- Customized design for material to be handled and for pick-zone aisles.

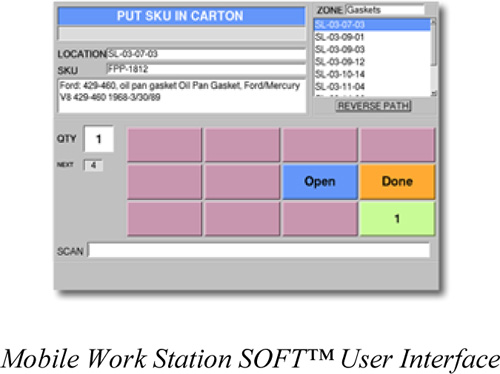

- Support item validation by scanning the item’s UPC or the source location.

- Support light-directed putting (and containers pushers as an option).

- Operate as nodes of an R/F (802.11b/g) network.

- Continuously optimize its operation, in real-time, based on pending work, job priority, and current vehicle location.

- Support real-time exception handling.

- Can provide the selector with two-way communication from any side of the workstation: voice, large or small monitors (standard CRT or touch-screen), lights and confirm buttons, carton pushers, keyboard and/or mouse, scanner.

- Powered by rechargeable batteries, capable of 10 or more hours of continuous operation between charges.

Interface with Host System

- Originally designed to operate as an independent module interfacing with a host system. In this mode, the host system performs order allocation and the fulfillment workstations receive orders as the locations from where to pick the items.

- Also may support an operation where the fulfillment system manages the inventory within the serviced pick zone(s), performing order allocation within the zone(s). This mode allows the fulfillment system to further improve the system productivity. Under these conditions, the fulfillment workstations receive orders as the SKUs required for the orders.

- Can report executed transactions back to the host system in real-time or as a batch process.

Dynamic List of Orders to Process

- Does not require a finite number of cut-off times through the day for order release from the host to the fulfillment system.

- Addition, deletion, and modification of orders in the list of orders to process are allowed at any time during the day.

- Selection of the best order to start next in a workstation is based, first, on order priority, and then, on current workstation location.

Adaptive Features

- Display to the selector the list of all pending jobs for the orders currently in the workstation, in an optimized suggested sequence, based on the current workstation location.

- Allow the selector to modify the suggested job sequence and re-optimizes the future jobs based on the selector’s decision.

- Allow the selector to relocate his workstation at any time and re-optimizes the future jobs based on the selector’s action.

- Allow the selector to scan any container not in the workstation and respond displaying all the pending transactions for the scanned container. Then, the selector can decide if he wants to process the container with his workstation, send the container to other zone, or leave it where it is.

Picking Path

- Support user-defined picking paths independent of location IDs.

- Allow easy addition and deletion of pick locations without re-labeling locations.

- Support picking from multiple pick zones with containers passing from zone to zone

Cartonization

- Supports cartonization

- As defined by the host system

- As decided by the selector

- As calculated by the fulfillment system

Virtual Batching

- Support endless loops as picking paths. Such loops do not have a beginning or an end.

- Allow selectors to add new containers to his workstation and to release containers from his workstation at any point of the picking loop.

- Allows selector to increase the order batch size beyond the number of cells in the workstation.

Reports

- A variety of reports available through the monitor in the workstation, that allows the selector to make better-informed decisions. Some of the report capabilities include:

- Order status.

- Container status.

- Selector productivity.

- Other custom required reports.

Long Aisles and/or Few Order Line-Items

- Support multi-step picking (i.e. pre-picking).