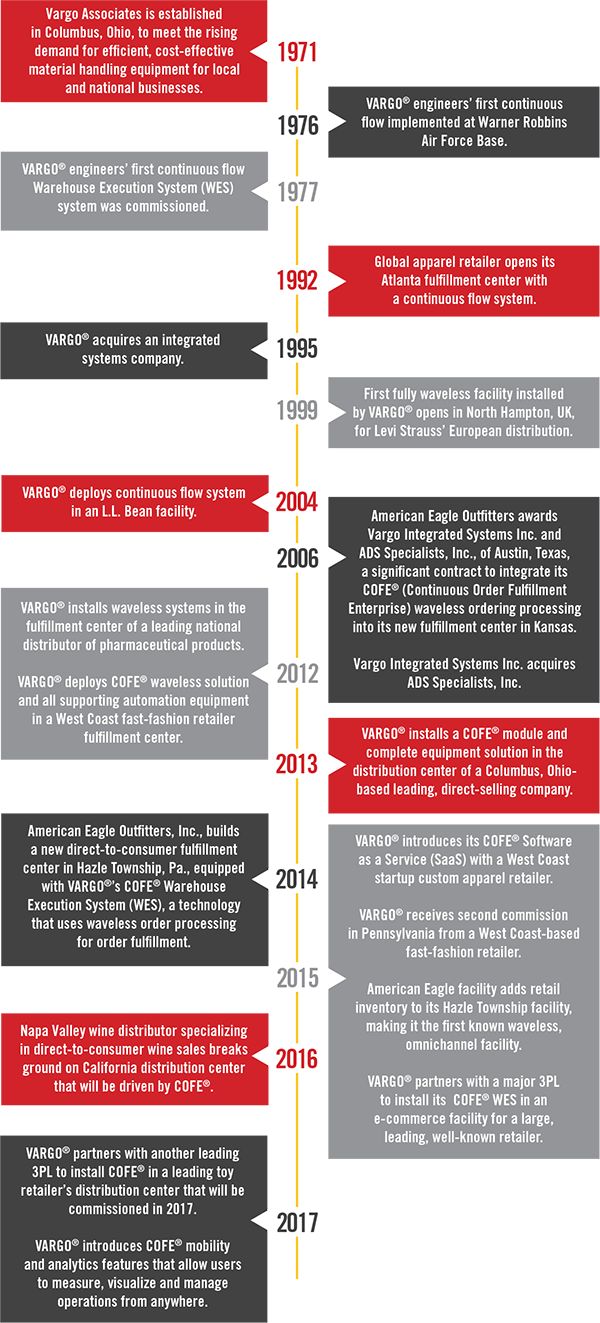

History of VARGO®

Since 1971, VARGO® has supported the operational needs of high-volume direct-to-consumer companies, retailers, wholesalers and manufacturers through our unique approach to complex fulfillment solutions. This graphic highlights a few of our milestones.

1971:

Vargo Associates is established in Columbus, Ohio, to meet the rising demand for efficient, cost-effective material handling equipment for local and national businesses.

1976:

VARGO® engineers’ first continuous flow implemented at Warner Robbins Air Force Base.

1977:

VARGO® engineers’ first continuous flow Warehouse Execution System (WES) system was commissioned.

1992:

Global apparel retailer opens its Atlanta fulfillment center with a continuous flow system.

1995:

VARGO® acquires an integrated systems company.

1999:

First fully waveless facility installed by VARGO® engineers opens in North Hampton, UK, for Levi Strauss’ European distribution.

2004:

VARGO® deploys continuous flow system in an L.L. Bean facility.

2006:

American Eagle Outfitters awards Vargo Integrated Systems Inc. and ADS Specialists, Inc., of Austin, Texas, a significant contract to integrate COFE® waveless ordering processing into its new fulfillment center in Kansas.

Vargo Integrated Systems Inc. acquires ADS Specialists, Inc.

2012:

VARGO® installs waveless systems in the fulfillment center of a leading national distributor of pharmaceutical products.

VARGO® deploys COFE® waveless solution and all supporting automation equipment in a West Coast fast-fashion retailer fulfillment center.

2013:

VARGO® installs a COFE® order consolidation module and complete equipment solution in the distribution center of a Columbus, Ohio-based leading, direct-selling company.

2014:

American Eagle Outfitters, Inc., builds a new direct-to-consumer fulfillment center in Hazle Township, Pa., equipped with VARGO®’s COFE®® (Continuous Order Fulfillment Engine) warehouse execution system, a technology that uses waveless order processing for order fulfillment.

2015:

American Eagle facility adds retail inventory to its Hazle Township facility, making it the first known waveless, omnichannel facility.

VARGO® introduces its COFE®® Software as a Service (SaaS) with a West Coast startup custom apparel retailer.

VARGO® receives second commission in Pennsylvania from a West Coast-based fast-fashion retailer.

VARGO® partners with a major 3PL to install VARGO®’s COFE® warehouse execution system in an e-commerce facility for a large, leading, well-known retailer.

2016:

Napa Valley wine distributor specializing in direct-to-consumer wine sales breaks ground on California distribution center that will be driven by COFE®.

VARGO® partners with another leading 3PL to install COFE® in a leading toy retailer’s distribution center that will be commissioned in 2017.

2017:

VARGO® partners with another leading 3PL to install COFE® in a leading toy retailer’s distribution center that will be commissioned in 2017.

VARGO® introduces COFE® mobility and analytics features that allow users to measure, visualize and manage operations from anywhere.

Become another success story on our timeline and discover the power of COFE®, the WES software that does for fulfillment what Lean did for manufacturing.

2018:

VARGO® adds workflows and updates to Gap Inc.’s Gallatin fulfillment center, with an automated storage and retrieval system.

VARGO® expands its growing software engineering team with the opening of the VARGO® Technology Center in Dublin.

VARGO® announces updates to its COFE® warehouse execution system software and COFEView, VARGO®’s business intelligence and reporting and management platform.

VARGO® partners with Kindred to integrate its robotic technology into COFE® at a global clothing retailer’s e-commerce facility in Nashville, TN.

VARGO® partners with global 3PL to redesign distribution center for large toy retailer.

VARGO® converts existing equipment into large scale fulfillment operation for Gap, Inc. Fresno, CA ecommerce fulfillment center.

2019:

VARGO® announces the opening of a sixth office, this time in Mason, Ohio.

KLX Aerospace Solutions distribution center in Miami goes live, featuring COFE® routing and warehouse control system functionality.

VARGO® partners with Fetch Robotics to implement a pilot project integrating autonomous mobile robots (AMRs) into COFE®® at a Gap Inc. fulfillment center in Phoenix, Arizona.

2020:

VARGO® is selected by Gap Inc. to design a robotics solution for its fulfillment centers in Phoenix, Arizona, and Rugby, England.

In response to the global Covid-19 pandemic, VARGO® introduces new COFE® WES software functionality that automates one-picker-per-aisle workflows to maintain safe social distance for warehouse workers.

VARGO® announces the creation of a preferred partner alliance with McCombs-Wall, Inc, providing access to VARGO® software and services to supplement McCombs-Wall product offerings.

VARGO® develops a cloud-based version of its Warehouse Execution System (WES) as part of VARGO® rollout of COFE® 4, synchronizing and optimizing e-commerce in leading retailers’ fulfillment centers.

VARGO® partners with Fetch Robotics to introduce integrated fulfillment solutions, combining the power of autonomous mobile robots with VARGO® execution software system to enable optimized picking.

VARGO® announces a partnership with Kindred to incorporate its artificial intelligence (AI) pick and place robotic solutions with VARGO® warehouse execution system (WES) to enhance both parties’ solutions for retail and e-commerce fulfillment.

2021:

VARGO® is selected by Old Navy to design a Ship from Store (SFS) solution for its store in Dallas, Texas, which will mimic Gap’s large fulfillment center features.

VARGO® expands operations in the Columbus region by investing over $4 Million and creating jobs in software, engineering, logistics and business analysis.

VARGOs® signs a distribution agreement with OPEX®, allowing the product to part of warehouse solutions that VARGO® proposes for clients.

2022:

VARGO® becomes an Employee-Owned Company.

VARGO® improves order capabilities for plus-size apparel brand to increase capacity and reduce order cycle times at its 1.1 million-square-foot facility in West Jefferson, Ohio.

VARGO® expands the Cincinnati office to keep up with continued growth; allowing their team to double in size with continued investment.

VARGO® completes a retrofit of Gap’s 550,000 square-foot Fishkill, NY campus including a new installation of its COFE® WES Continuous Order Fulfillment Execution software.

VARGO® completes a new, 800,000 square-foot, customer experience center in Longview, TX for Gap, Inc., including the installation of its COFE® WES Continuous Order Fulfillment Execution software.

VARGO® completes and enhancement and expansion of Gap’s Fresno, CA facility, including the addition of several COFE® modules and VARGO® WES Continuous Order Fulfillment Execution software.

VARGO® upgrades distribution for a major beauty retailer with a multi-project initiative that expands capacity and improves productivity.

VARGO® installs COFE® warehouse execution system in a world renowned, high-end fashion retailer’s North Carolina fulfillment center to drastically improve peak records.

VARGO® implemented a custom-designed solution for a national tire retailer, reducing operating costs by getting closer to demand and reducing labor.

VARGO® helps WineDirect to meet increased demand for home wine delivery by expanding their facilities to increase efficiencies, double processing capacity and allow for shorter order cycles.

2023:

VARGO® promotes COO and President, Bart Cera, to CEO after over 16 years with the company.

VARGO® transforms Arizona and New Jersey authentication centers for luxury consignment retailer, The RealReal.

VARGO® expands processing capabilities at two Gap sites to process up to 1M DTC units/day.